Détails du produit

1. Application

This adhesive is suitable for substrates such as BOPP, PET, PP, coated paper, and pearlescent film. Adhesion 400g ~700g/25mm(adjustable). The long-term temperature resistance can reach above 80°C. It can be labeled at a low temperature of minus 20°C.

Composition |

Chemical Name |

UV light curing hot melt pressure sensitive adhesive |

| Type (single product or mixture) |

Mixture |

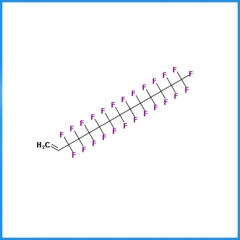

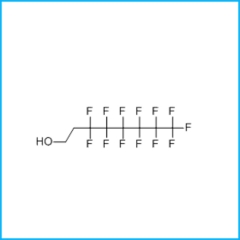

| Chemical name of main components |

Content(% |

| Acrylic ester copolymer |

≥99% |

| Ethyl acetate |

≤1% |

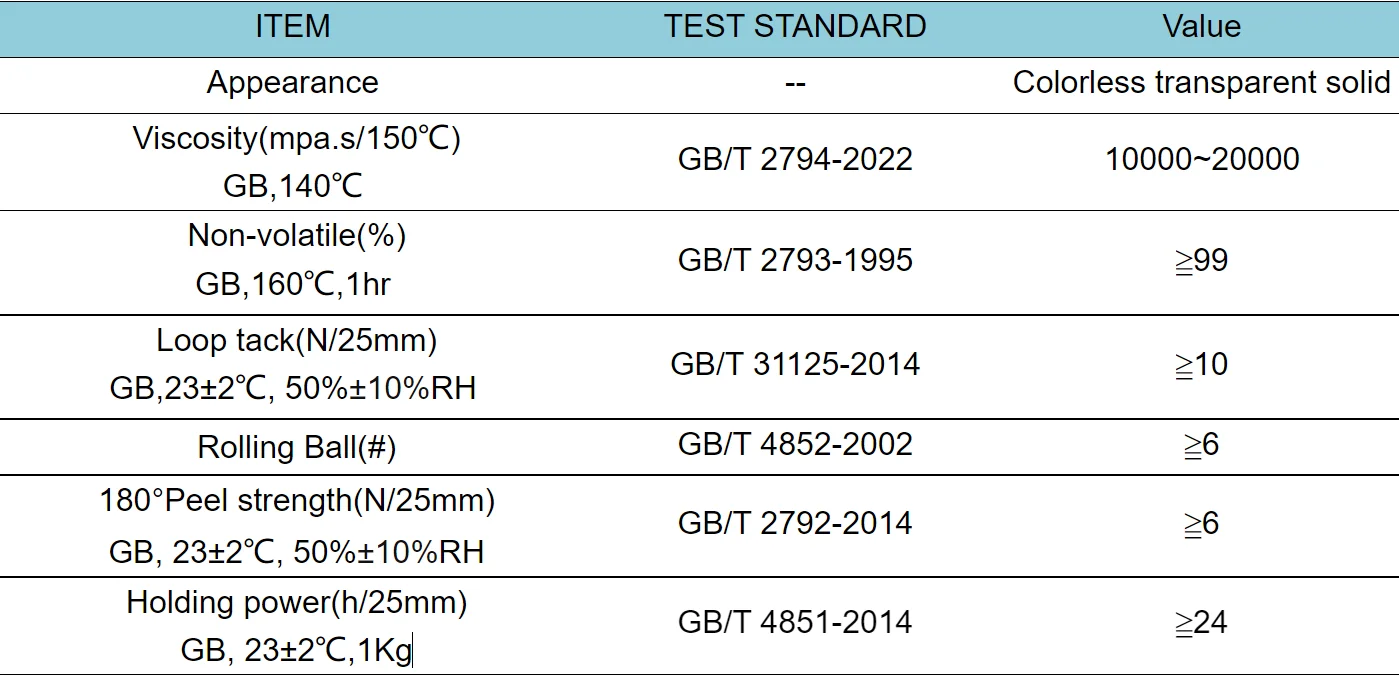

2. Performance

| Composition of test piece |

|

-----Substrate 50μmPET film -----Adhesive 25μm dry ----- Release paper, double-sided silicon release paper |

| Curing condition |

Use UVC band to make it cure |

| Mechanism of UV curing |

The photoinitiator in the UV glue generates free radicals to abstract hydrogen under the UVC band to form crosslinks. |

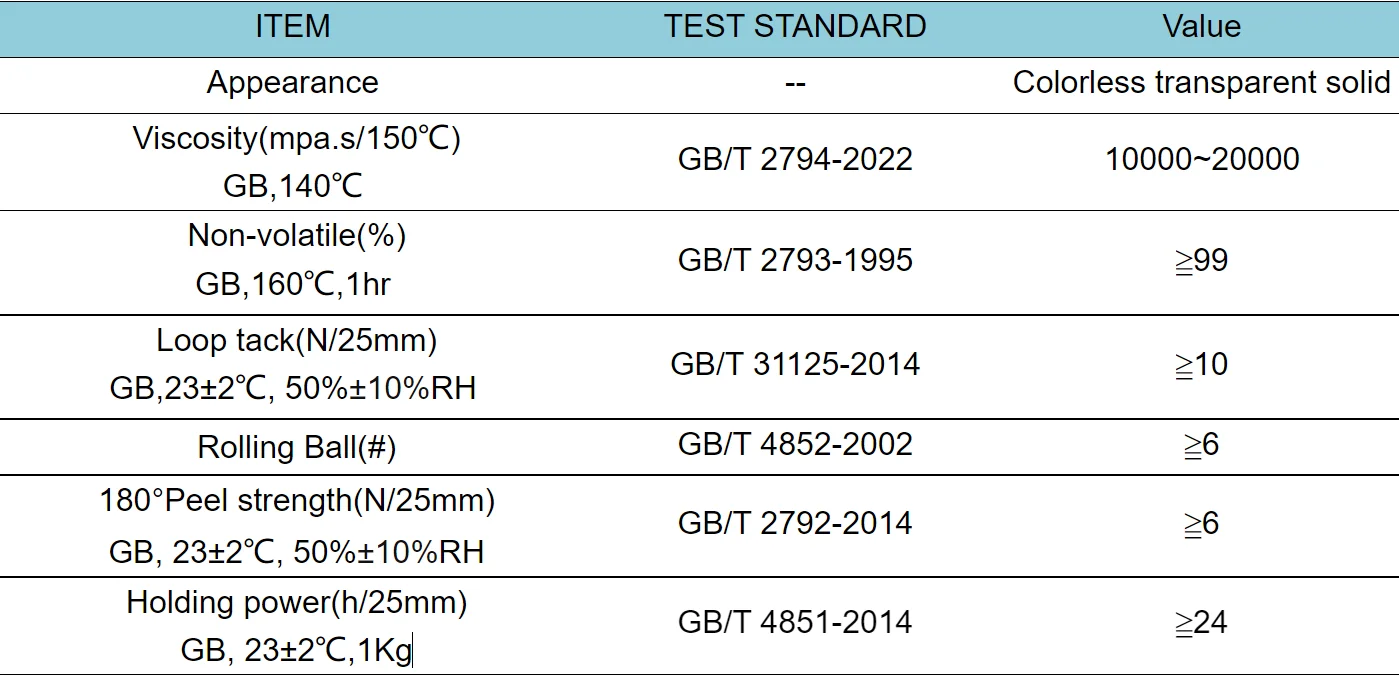

Physical and chemical indicators

3. Precautions during coating

3. Precautions during coating

1.This adhesive cannot be mixed with other adhesives. Clean the container, glue pump, rubber hose and coating head before use.

2.This product is a UV-curable hot-melt pressure-sensitive adhesive, which is solid at room temperature and should be protected from light during transportation and storage.

3.Gluing thickness: coating according to customer needs.

4.This adhesive can be used as a removable label adhesive, and can be applied with low weight pressure sensitive adhesive.

5.Adjust the energy according to the level of adhesion requirements. The specific curing energy can be referenced according to the following data.

| Energy mj/cm2 |

180°Peeling force /N |

Annular initial adhesion /N |

Holiding power/25℃/h |

Thickness/μm |

| 25 |

6 |

10 |

≥24 |

25 |

Remark:The test substrate is 50 μm PET film, and the coating method is direct coating;

This data is for reference only, and the specific data shall be determined according to customer needs.

The curing of UV hot melt adhesive is closely related to the energy of UV lamp and the speed of coating. The substrate used for coating is different, and the energy and speed of the coating need to be adjusted accordingly.

4.7 La colleuse à platine est chauffée à environ 150 ± 10 ° C et placée dans la boîte à colle, prête pour le revêtement.

4. 8 Exigences de température de la tête de revêtement : ajuster en fonction des conditions de l'équipement et du processus.

4. 9 Vitesse d'enduction : ajustée en fonction de l'épaisseur de la colle et de l'énergie de la lampe UV .

4. Mûrissement du ruban

Afin que les performances de l'adhésif atteignent une valeur stable et que la force de cohésion de la colle soit proche de la valeur maximale, le ruban enduit doit être stocké pendant 24 heures avant d'être testé, traité ou utilisé.

5. Stockage adhésif

La durée de validité de l'adhésif est de six mois et la température de stockage est de 25 ± 5 ° C, stocké dans un endroit ventilé, sec et frais, et à l'abri de la lumière.

français

français English

English русский

русский español

español العربية

العربية